Application case of pulse exchange ion rod in electrostatic removal before and after film coating

Project Background:

In the laminating process of the printing and packaging industry, static electricity is easily generated due to film friction and peeling, leading to issues such as impurity adsorption and misalignment during lamination, as well as potential safety hazards. To address this pain point, a packaging materials company has abandoned the traditional ion fan, which has proven ineffective, and introduced a pulse AC ion rod static elimination solution.

Solution

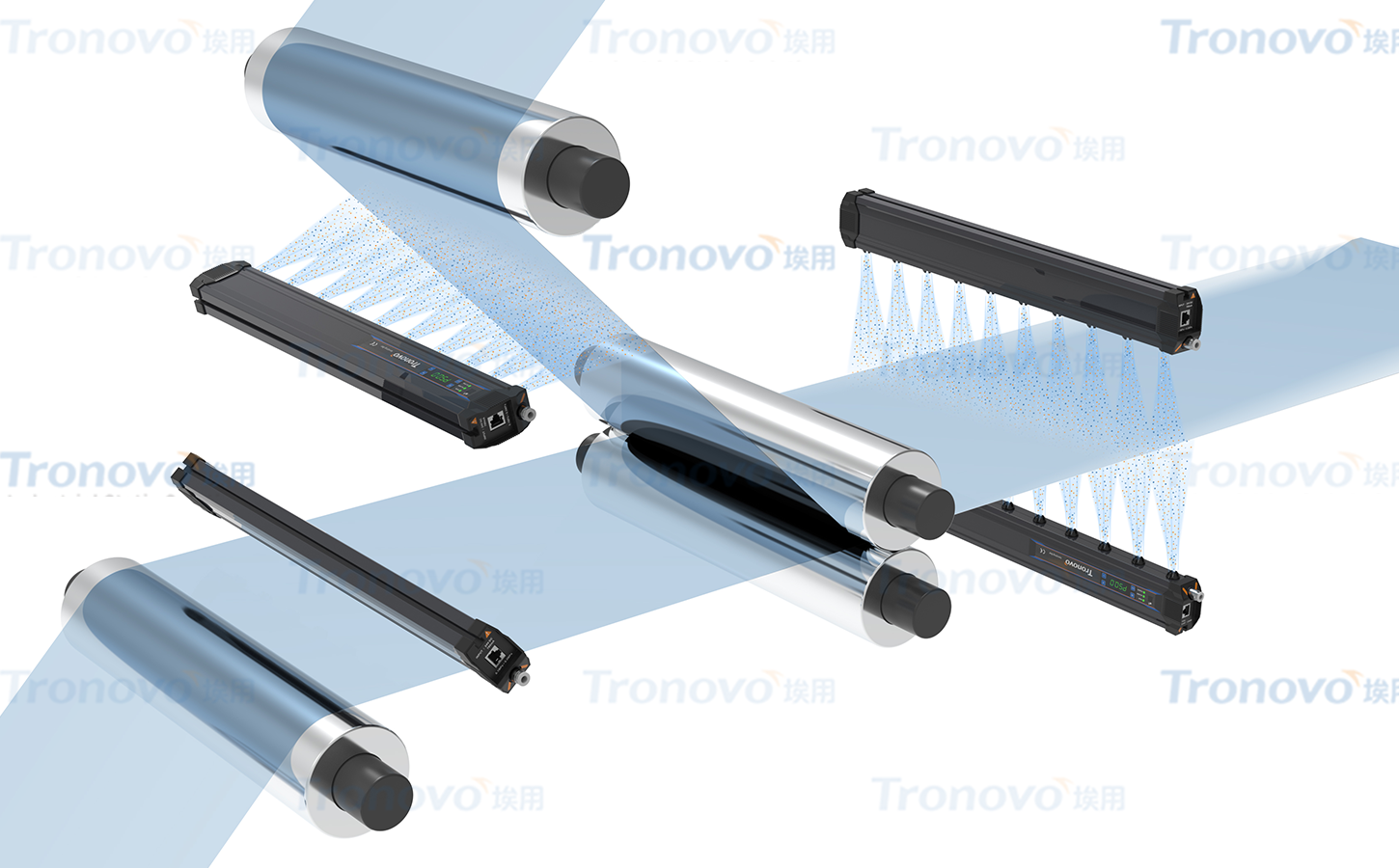

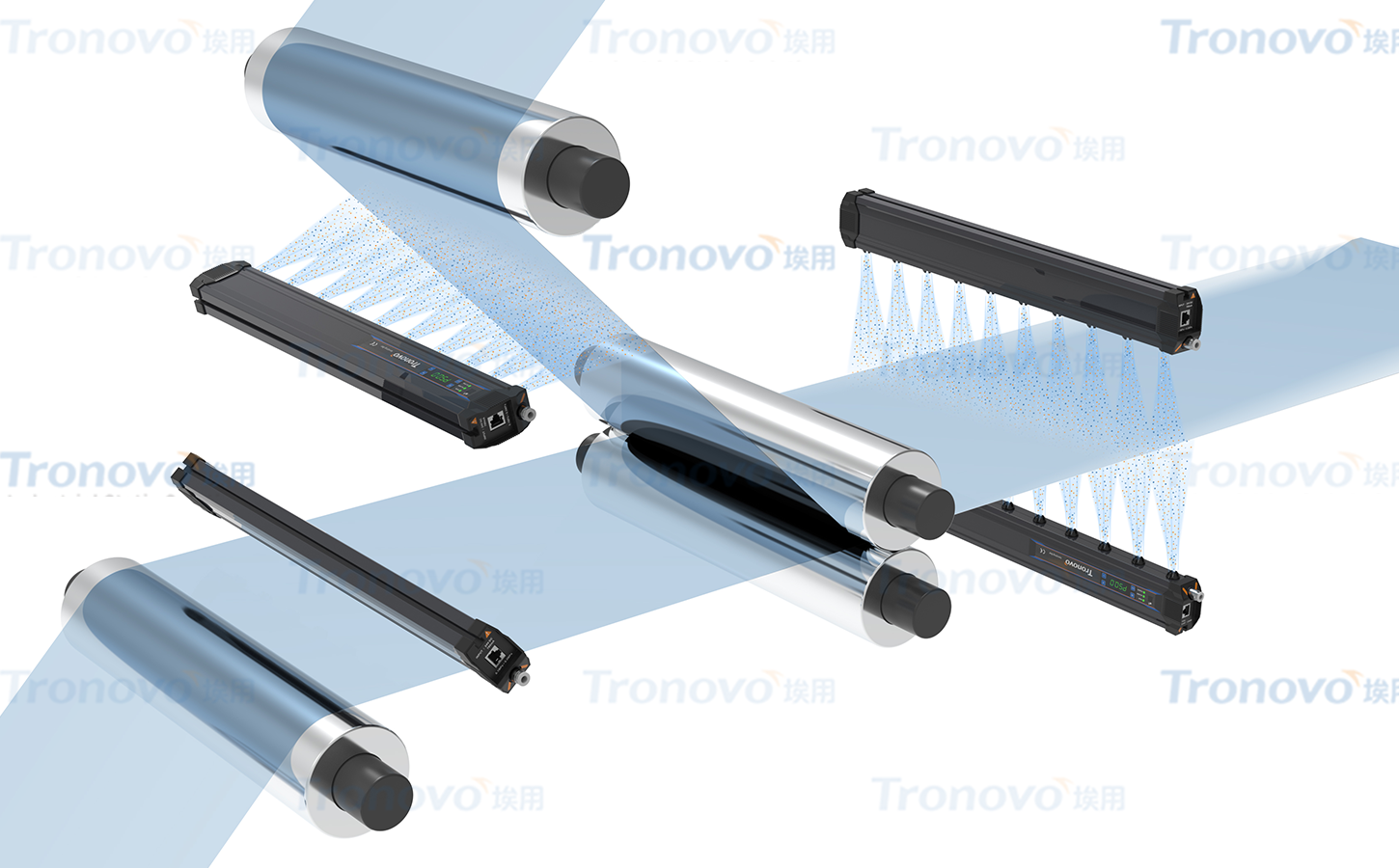

The solution adopts a dual-node deployment of "pre-treatment before film covering + secondary elimination after film covering": an integrated pulse AC ionizing air bar is installed above the substrate conveyor roller before film covering to eliminate static electricity and impurities; after film covering, ionizing bars are installed near the discharge port roller and the winder to eliminate residual static electricity from the composite film. This pulse AC ionizing air bar can be adapted to the production line speed adjustment parameters and is linked with the main control system to ensure the stability of static electricity elimination.

The application has achieved remarkable results

The product non-conformance rate has been reduced from 8%-10% to below 1.5%, the effective operation time of the production line has been increased by over 10%, the potential safety hazards of static electricity have been completely eliminated, and the equipment maintenance and energy consumption costs have also been significantly reduced, providing a feasible model for static elimination in the industry's laminating process.