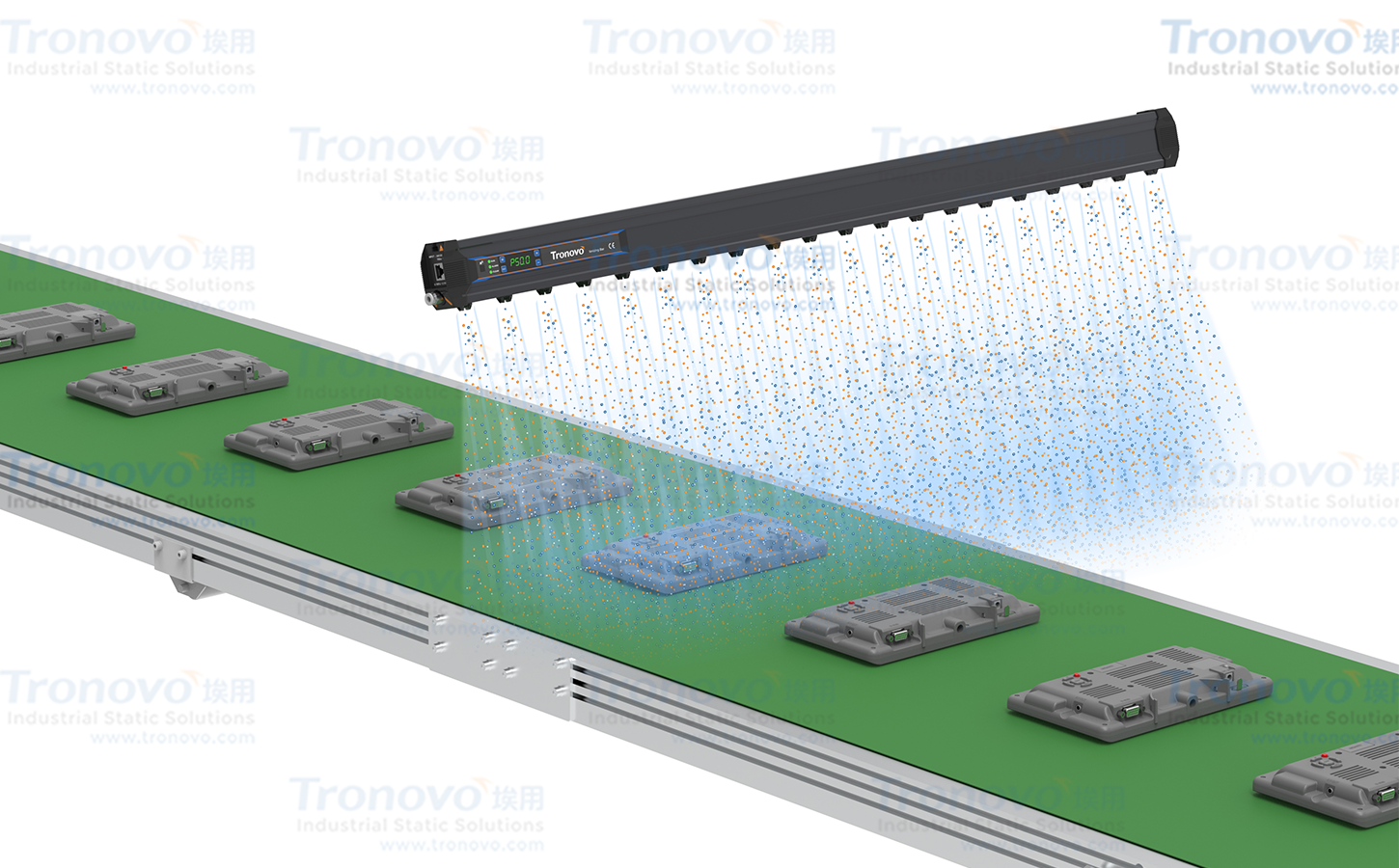

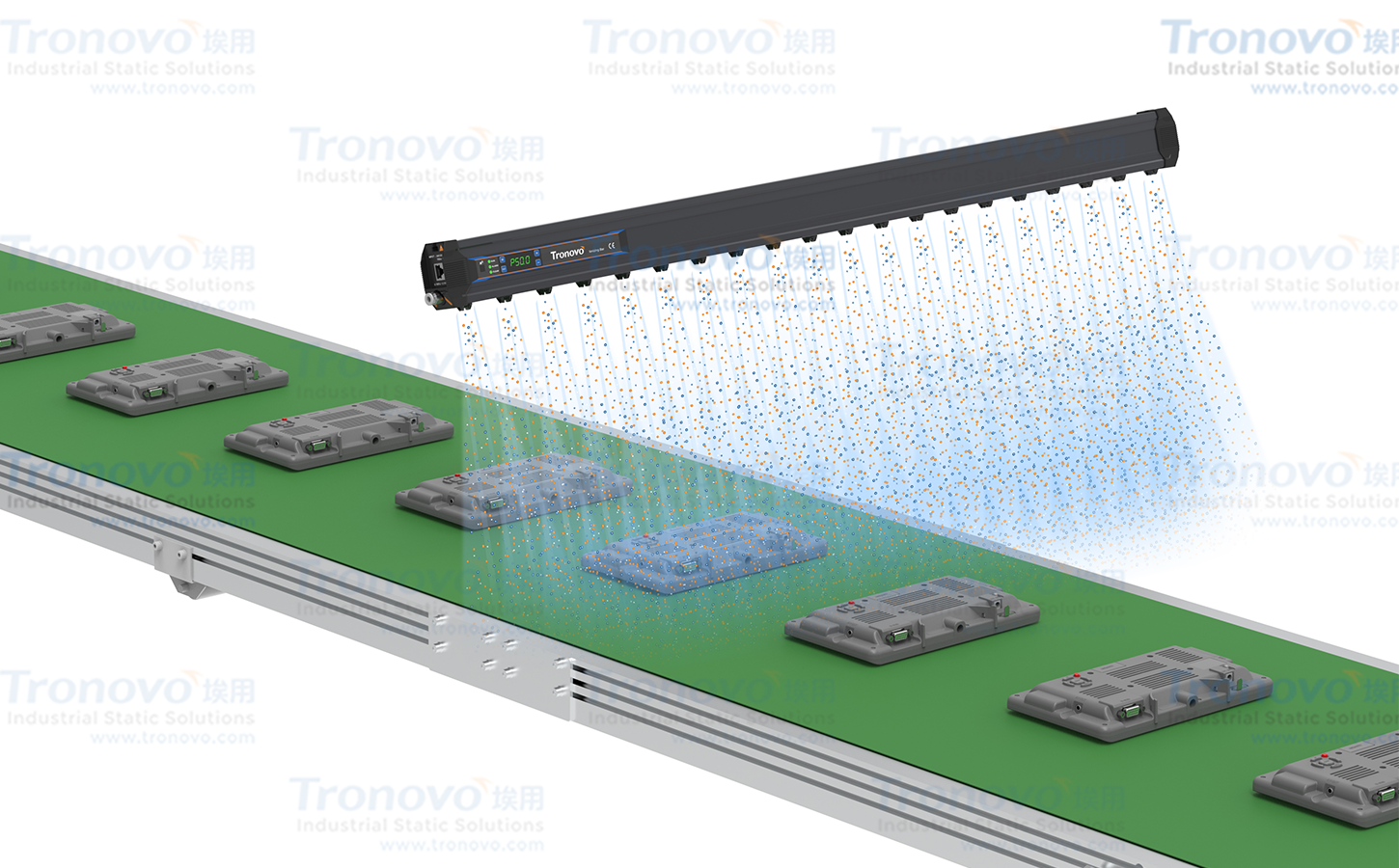

Efficient static elimination, pulse ionizing bar power panel clean production

Project Background:

In the panel manufacturing process, the accumulation of static electricity is the invisible killer that leads to the decline of yield. Due to material friction and equipment operation, the surface of the panel is easily charged, adsorbing suspended dust in the air, causing a series of quality problems such as appearance defacement, uneven coating, abnormal circuit contact and so on. This not only increases the cost of cleaning and rework, but also seriously affects the efficiency of the production line and the consistency of the product.

Solution:

In order to completely solve these 1 problems, the production line is equipped with pulse AC ionizer rods at key stations, and the static elimination rods are accurately set up above the conveyor belt, so that the ion coverage completely coincides with the travel track of the panel. During operation, the ionizing bar continuously outputs a balanced positive and negative ion flow, which can efficiently neutralize the electrostatic charge on the surface of the panel, completely eliminate the electrostatic adsorption force, and block the dust adhesion from the root.

Implementation effect:

After the implementation of the scheme, the cleanliness of the panel surface is significantly improved, the appearance defect rate is greatly reduced, and the frequency of manual wiping is reduced, which provides a reliable guarantee for high-precision and high-efficiency continuous production.