High-speed film slitting electrostatic nemesis: pulsed DC ion bar to help efficient intelligent production

Project Background:

In the process of high-speed slitting and unwinding of thin film materials, electrostatic accumulation is the core bottleneck that affects the yield and production efficiency. It is not only easy to cause adhesion between films, untidy winding, resulting in curling and offset, but also adsorb surrounding dust to pollute the surface of the product, which is more likely to interfere with the sensor signal, resulting in false alarm or even shutdown of the equipment, seriously restricting high-speed continuous and intelligent production.

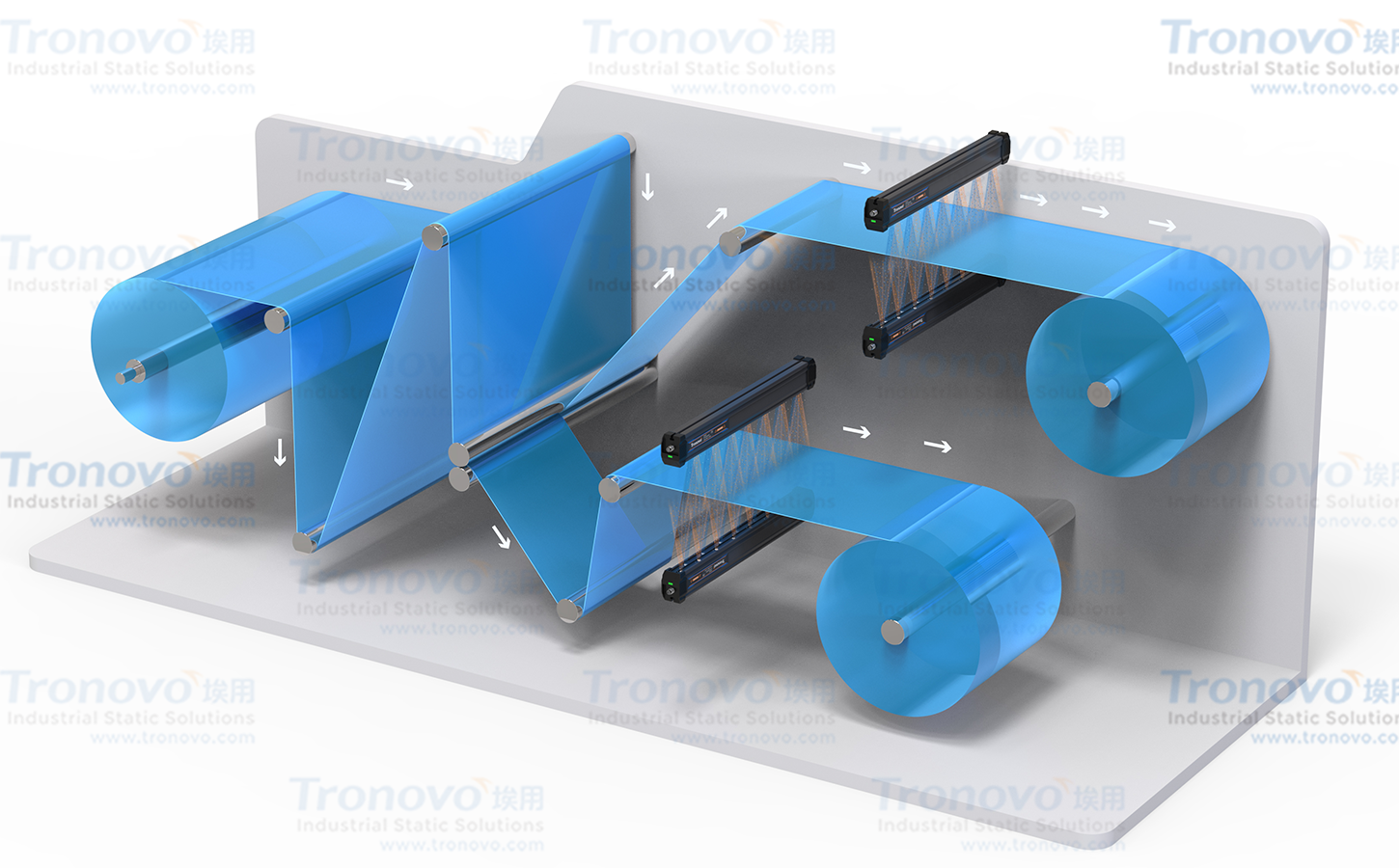

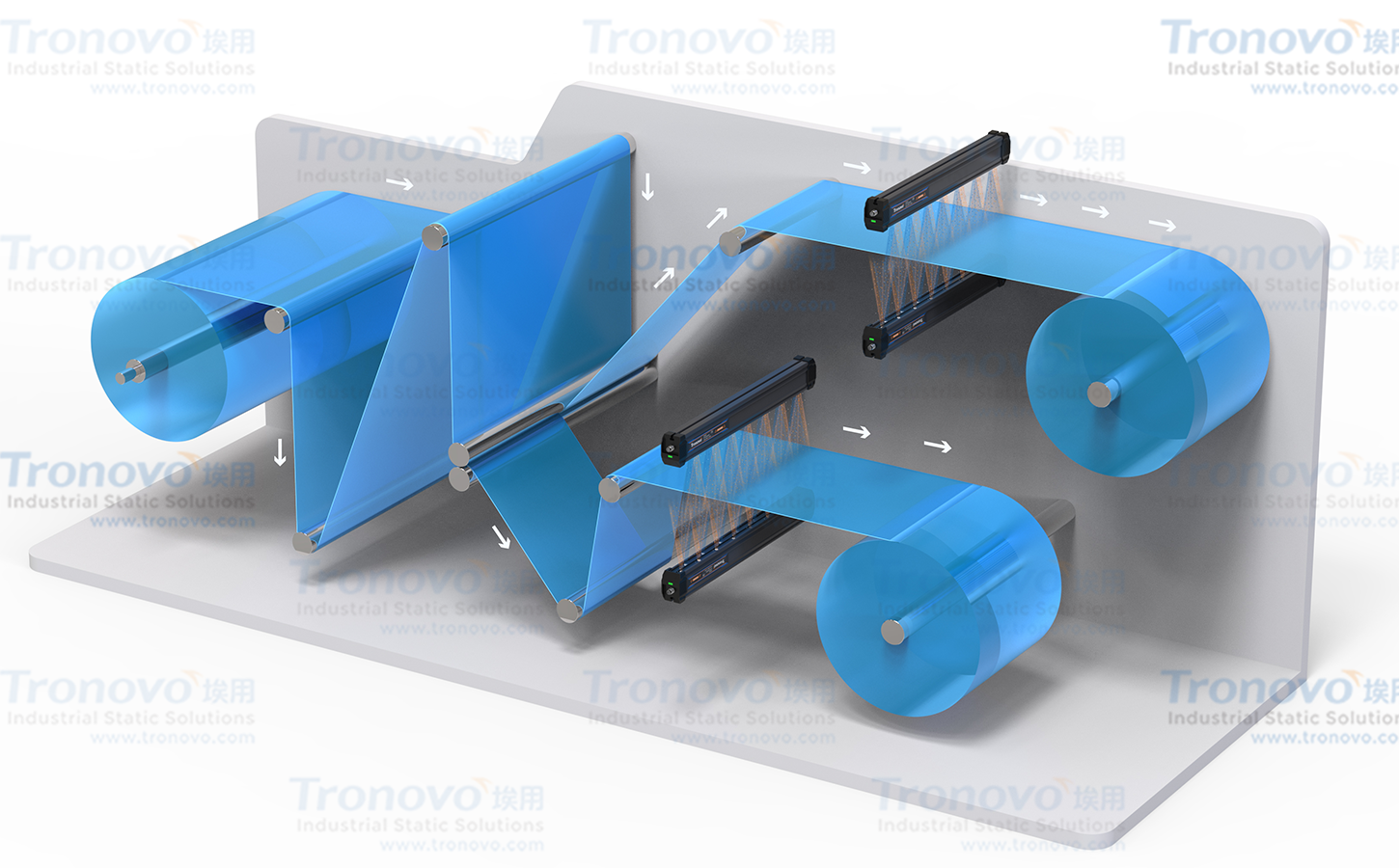

Solution:

In view of the above pain points, it is recommend to install a special pulse ionizer bar in the winding area. The static elimination rod can efficiently neutralize the static charge on the surface of the high-speed moving film by emitting balanced positive and negative ions and accurately covering the film surface with a stable airflow. Compared with the traditional AC static elimination method, the pulsed DC ionizing bar has faster response, larger action distance and better ionizer balance performance, and is especially suitable for extremely high-speed and wide-width film production lines.

Core advantages:

The practical application shows that the scheme can significantly improve the quality of winding, eliminate irregular stacking and slitting deviation, avoid surface defects caused by electrostatic adsorption, and ensure the stable operation of testing equipment. Pulsed DC ionizing bar has become an indispensable key component for high quality film manufacturing, helping enterprises to reduce losses, increase production capacity, and accelerate towards a new mode of production with high reliability and intelligence.