Application Case of Ionizer Air Rod Applied to Glass Electrostatic Precipitation_复制

Project Background:

In the manufacturing industry, the glass surface is prone to accumulate static electricity due to friction, cutting and transmission processes, and adsorb small pollutants such as dust and wool floating in the air. This kind of pollution not only affects the appearance of the product, but also causes serious interference to the subsequent deep processing processes (such as coating, printing, interlayer, etc.), resulting in uneven coating, imprinting defects and even adhesion decline, directly reducing the qualified rate of finished products, resulting in additional cleaning costs and capacity loss. Therefore, the effective removal of static electricity and adsorbed impurities has become a key link to improve the quality of glass and production stability.

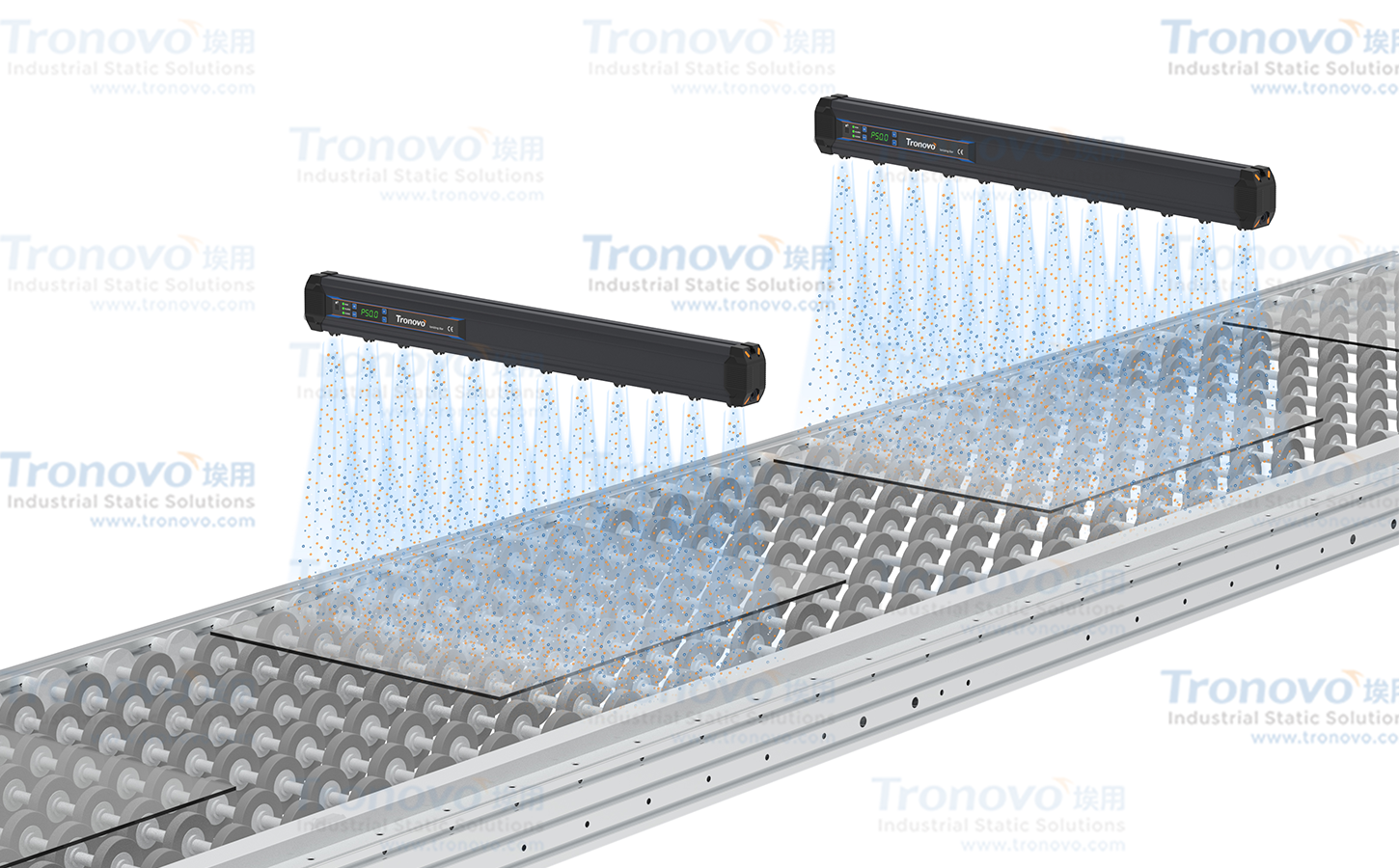

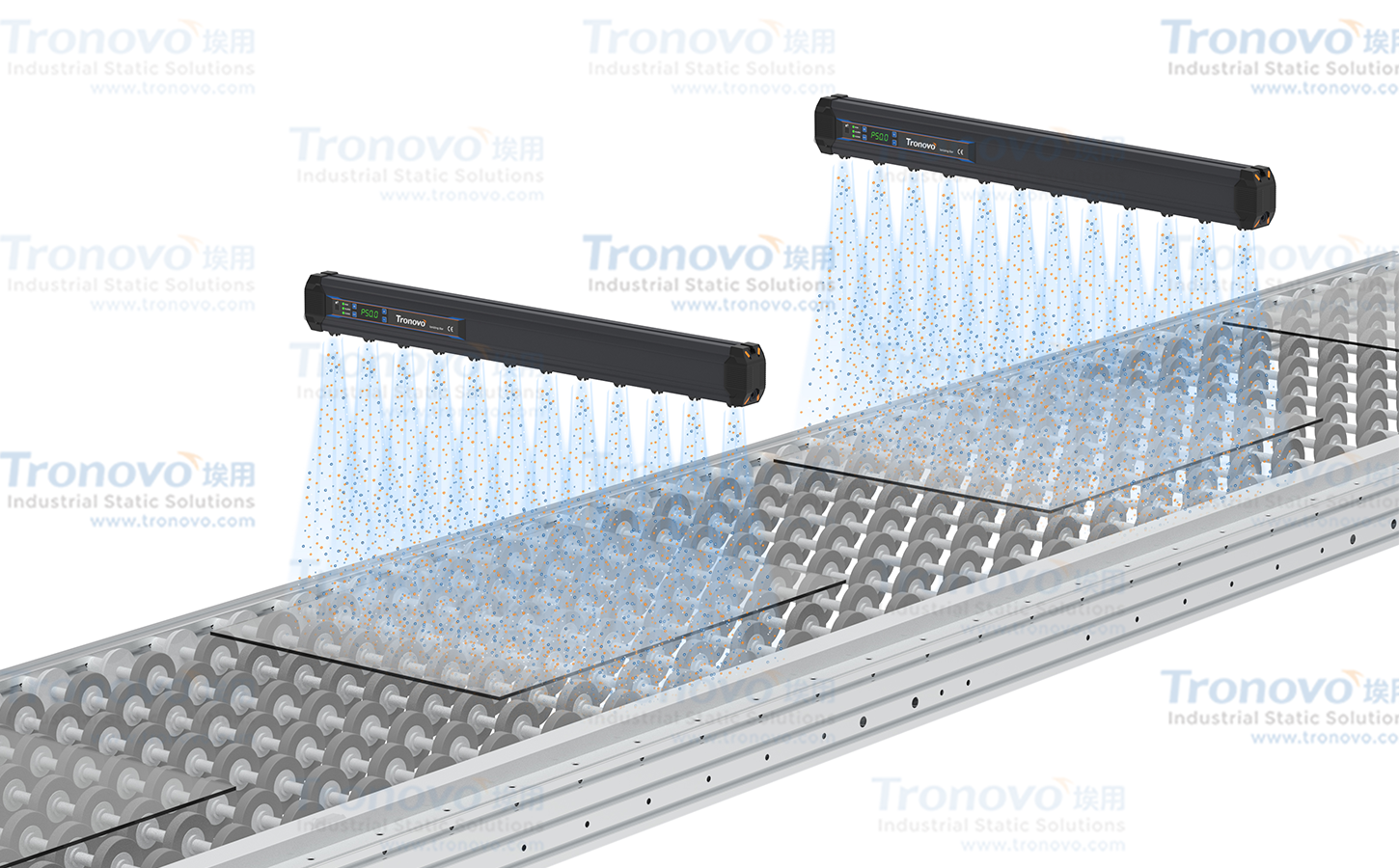

Solution:

In order to meet these 1 challenges, a large automobile manufacturer introduced pulsed AC ionizer rods, which were installed in key stations after cleaning and drying in the pretreatment section and before coating or printing. The digital display ionizing bar can be based on intelligent control mechanism, alternately produce a large number of positive and negative ions beam, and with the help of compressed air to cover a large area of glass surface, quickly neutralize the electrostatic charge, fundamentally remove the electrostatic adsorption of particles. Its design pays special attention to cover uniformity and adaptability, not only can efficiently deal with flat glass, but also can deal with curved surface, hollow, special-shaped and other complex structure glass, to achieve three-dimensional 360 degrees without dead angle electrostatic removal, effectively avoid local charge residue.