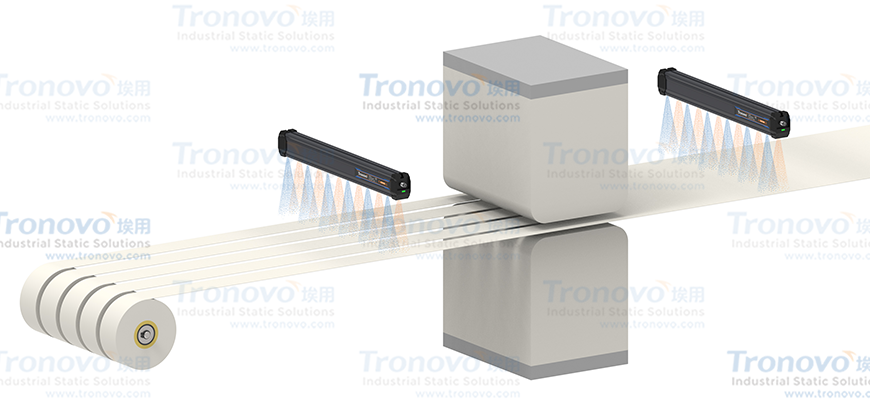

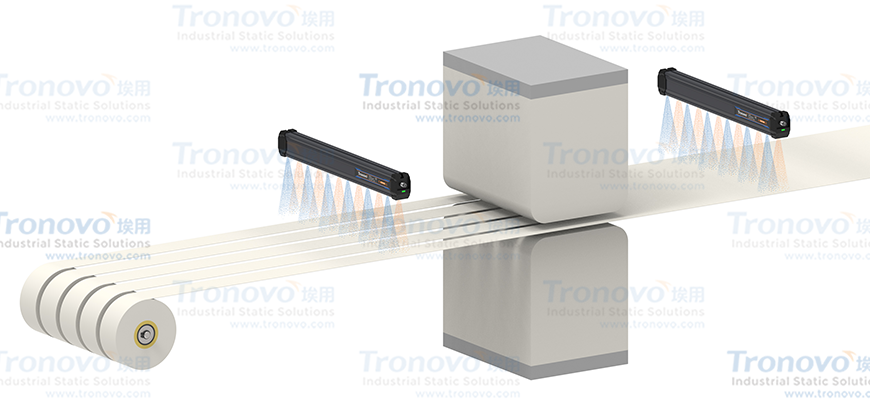

Application case of ionizer bar in slitting process

Project Background:

In the high-speed slitting operation, a large amount of static electricity is generated due to violent friction between the cutter and materials such as film and paper, resulting in uneven winding of the finished product, disordered stacking, dust adsorption on the surface and even electric shock tingling of the operator-these are typical phenomena of electrostatic interference. It not only affects production efficiency, but also poses a threat to product appearance quality and personnel safety.

Solution:

In view of these 1 pain points, the pulse DC static elimination bar has become the key equipment for static control in the slitting process. After being installed at the discharge position of the slitting tool, the ionizer bar can continuously generate a balanced positive and negative ions flow, quickly neutralize the electrostatic charge on the surface of the material, and prevent the electrostatic adsorption effect from the source. After slitting, the material can be smoothly separated and smoothly transmitted, and the winding is neat and free of adhesion, effectively eliminating the appearance pollution caused by electrostatic dust collection.

Core advantages:

Pulsed ionizing bar has three core advantages: first, wide ions coverage, full effect on large width materials, no dead angle of power dissipation; Second, the response speed is fast, electrostatic neutralization can be completed at the moment of slitting, without affecting the production line rhythm; Third, all of them adopt safe low-voltage power supply, have no electric shock risk, conform to strict production safety standards, and have stable and reliable performance.