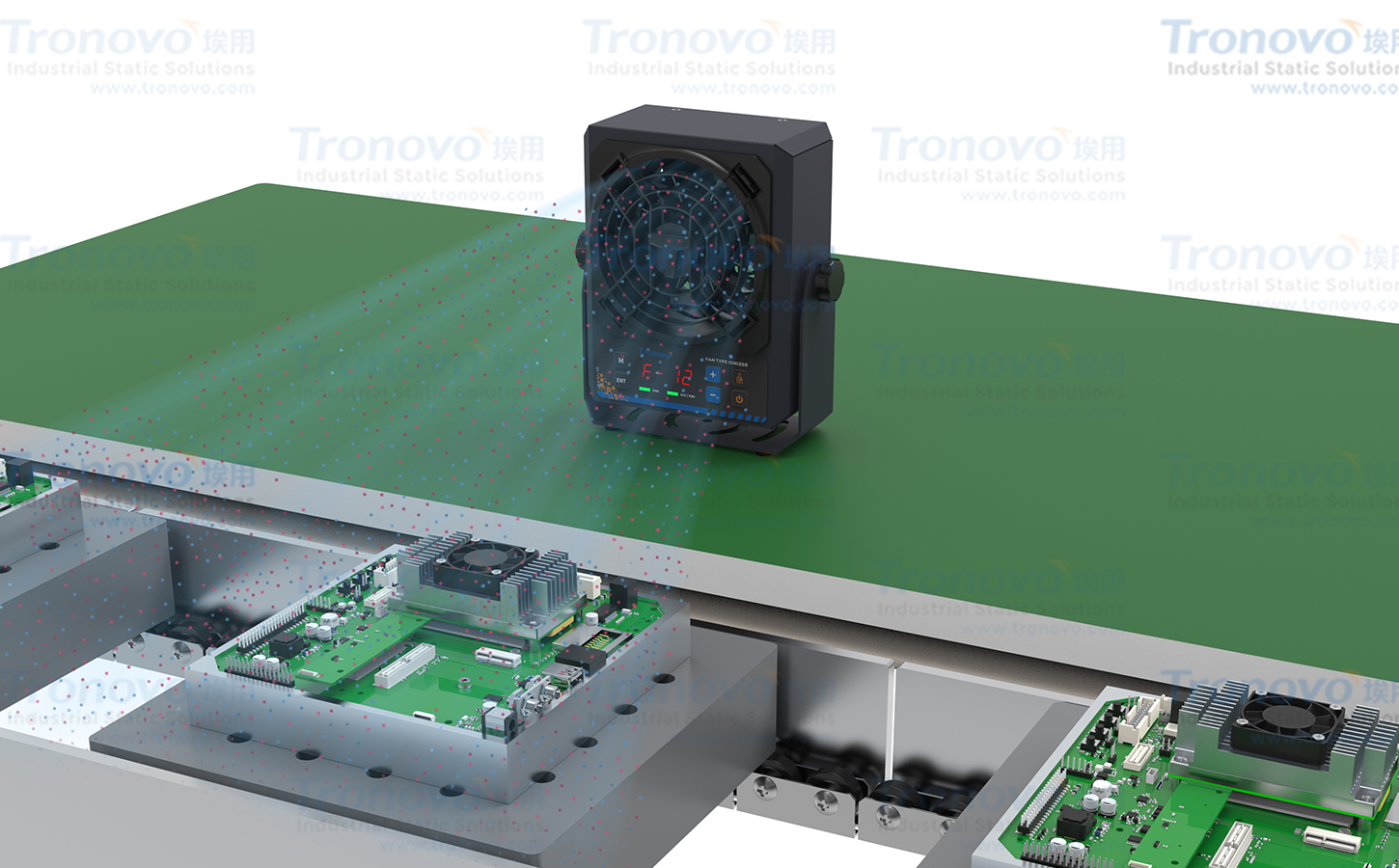

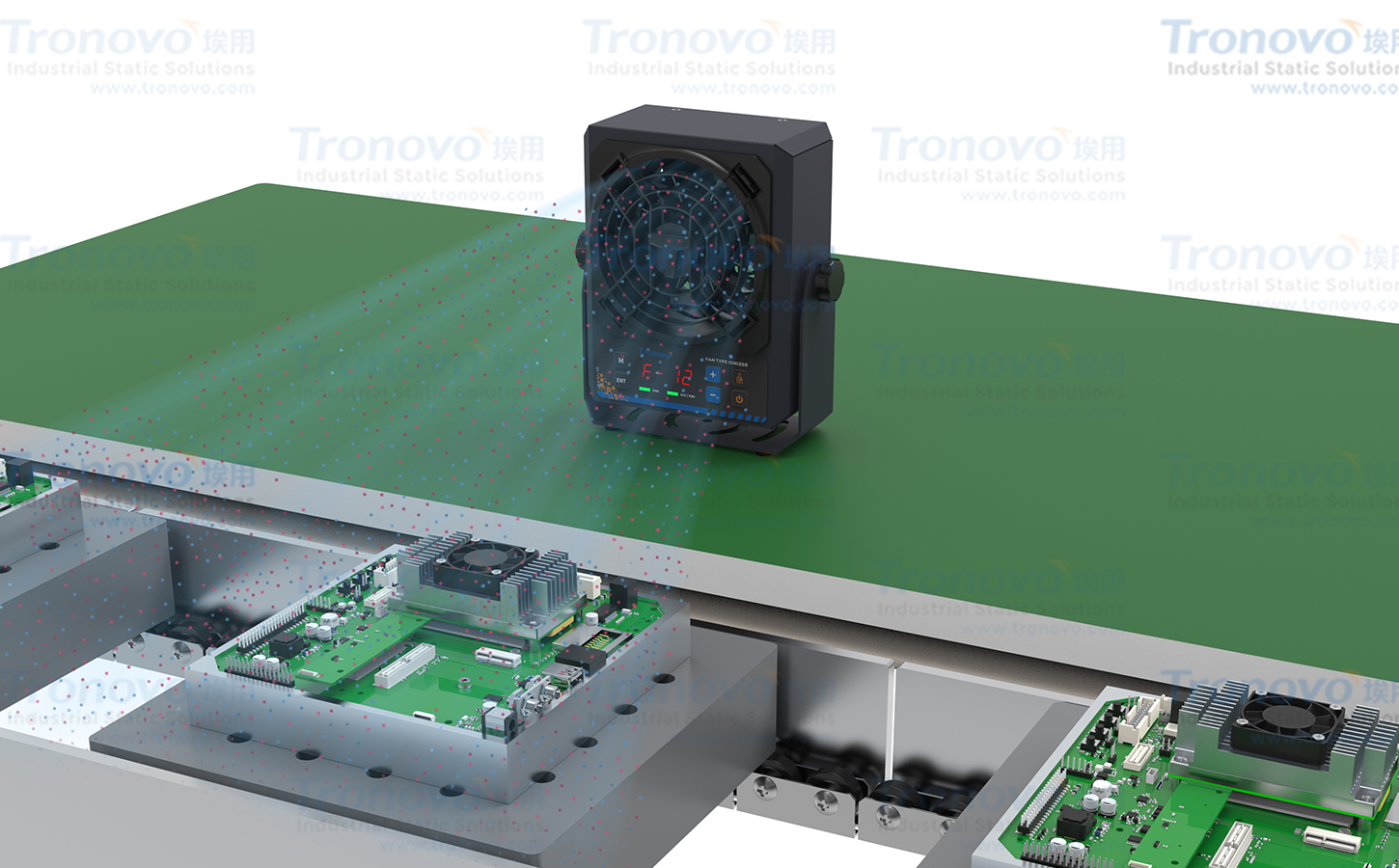

Application case of ionizer fan in anti-static of circuit board

Project Background:

In the production and assembly of circuit boards, electrostatic problems have always been a key factor restricting product quality. When the circuit board is in contact with the chip, the static electricity generated instantly can easily break down the internal precision structure of the chip, causing abnormal circuit function; at the same time, the dust adsorbed by static electricity will adhere to the surface of the component, which not only increases the cost of material loss, but also directly leads to a sharp decline in product yield, seriously affecting the stability of the production process.

Solution:

In order to solve these 1 production pain points, high-frequency ion fans can be deployed in a targeted manner. The self-cleaning ionizer wind can stably output balanced positive and negative ions currents, quickly neutralize the electrostatic charge accumulated on the surface of the object, and avoid the component from the source due to electrostatic damage. In practical applications, an intelligent digital ionizing fan is installed directly above the circuit board assembly station, and the ions beam released by the fan can eliminate the static electricity generated during the operation in real time. At the same time, the formed airflow protection layer can effectively isolate the static electricity interference of the surrounding environment, significantly improve the assembly accuracy, and provide reliable technical guarantee for the manufacturing quality of the circuit board.