Electrostatic removal of lightweight injection molded parts

For ultra-small injection molded parts, in order to solve the problem of material accumulation caused by electrostatic adsorption, the traditional static elimination method may be difficult to implement due to size limitations. For example, the humidification method may not be effective because the humidity is difficult to accurately control, while the contact static elimination device may not be fully effective because the contact area is too small. Therefore, there is a need 1 a solution that can not only adapt to ultra-small size, but also can effectively remove static electricity.

Question:

1. Product blanking flying randomly: The use of ordinary compressed air will cause injection molded parts to fly everywhere during blanking.

2. The injection molded parts are adsorbed on the mold: static electricity will cause the light injection molded parts to be adsorbed with the mold, and the blanking port will accumulate and block materials.

3. Affect the work efficiency: the adsorption caused by static electricity affects the operation of the machine and needs to be solved manually.

Solution:

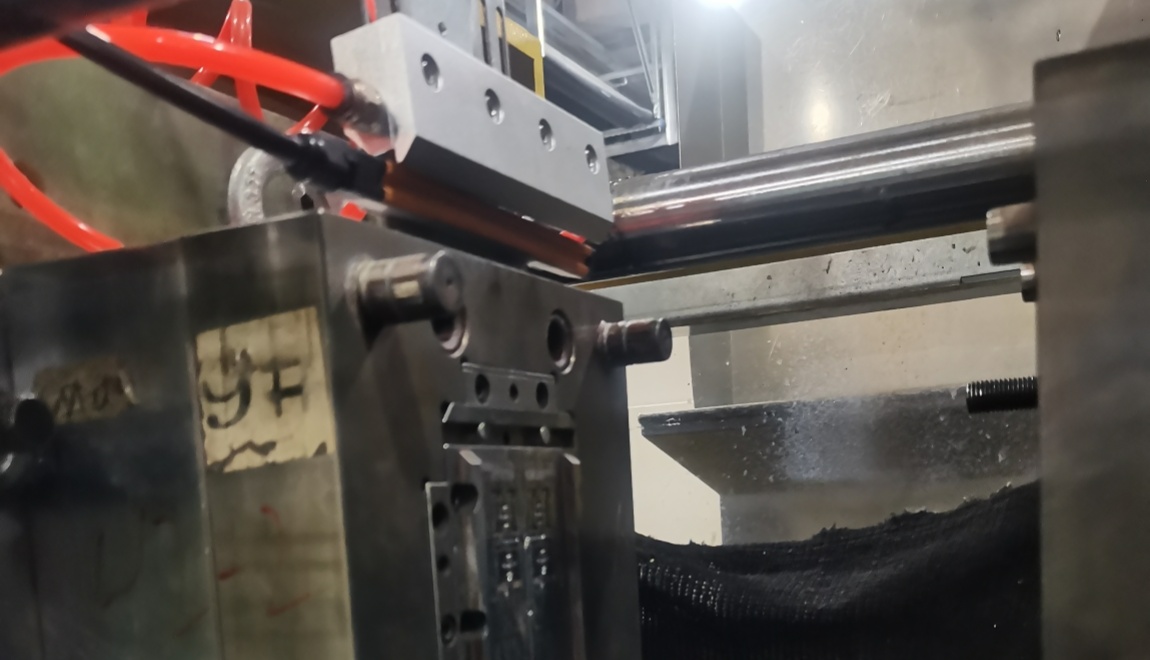

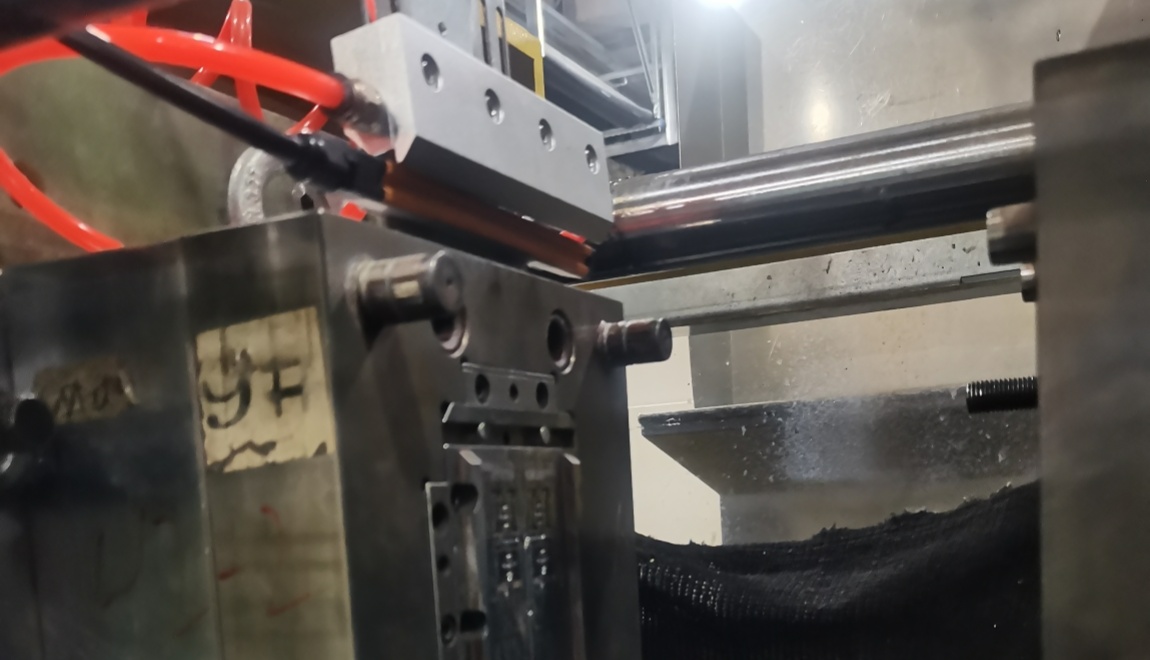

1. Install the ion air knife directly above the mold discharge port.

2. connected with clean compressed air, its strong ion air flow can remove static electricity and dust and foreign bodies of injection molded parts.